Successful conflict resolution of engineering design disagreement.

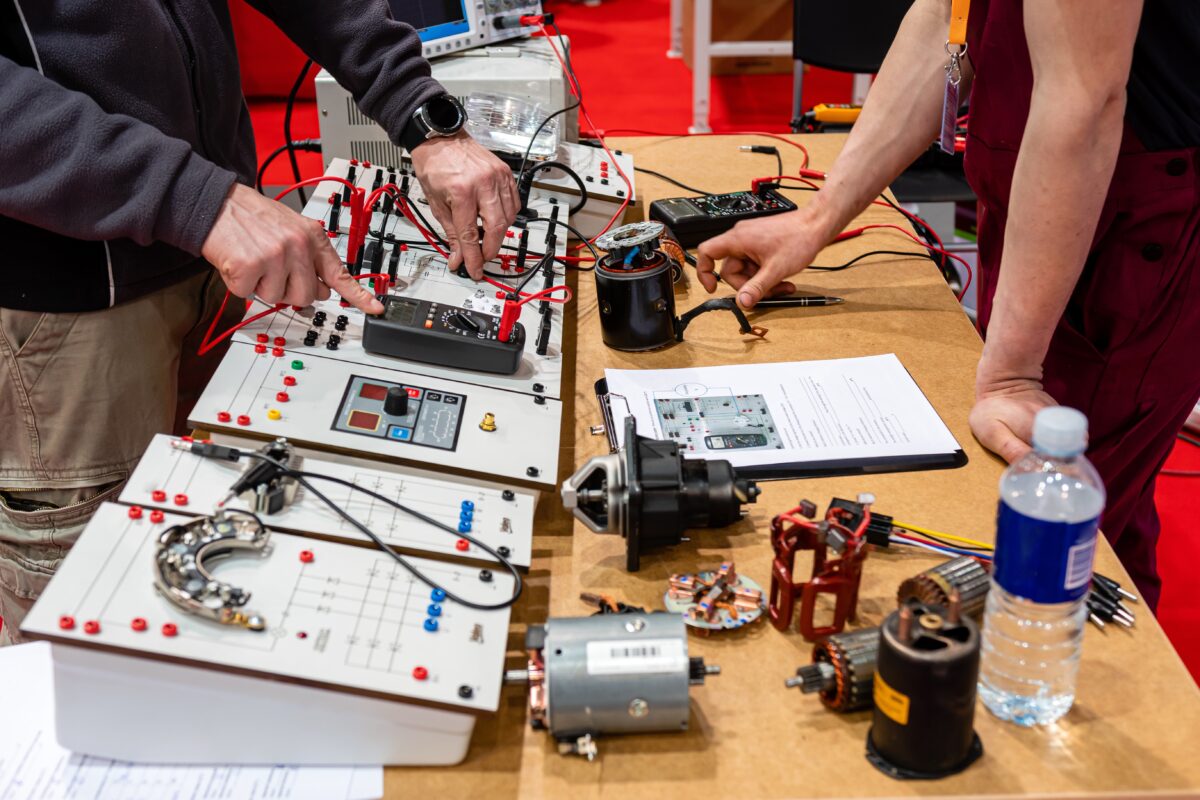

The days of solitary electronic circuit board design and development have virtually disappeared. Sure, there are still a few DIYers out there building prototypes, but most PCB innovation today results from a complex process with multiple stakeholders. A different person may be responsible for sourcing components, designing the board layout, performing operational simulations, and testing prototypes in-house. There are also fabrication and assembly house professionals and, for critical or hazardous environment applications, like automotive, industrial, aerospace and defense, external laboratory testing may be required. Additionally, there may be co-designers on your team; including mechanical engineers for electromechanical device design.

With so many persons having a stake in the success of product design and development, there is likely to be some friction and disagreement. If not mitigated, team collaboration, workflow, vendor relationships, product quality, and client satisfaction can suffer. Therefore, knowing and implementing effective conflict resolution in engineering strategies is essential.

Engineering Conflicts: Types and Causes

It is fairly common to adopt and implement a risk management plan to optimize the overall profitability of the investments that go into product design and development. Prior to implementation; however, it is important to understand the potential sources of risk that exist in the process. Similarly, creating a plan for conflict resolution necessitates an understanding of potential sources of conflict, as listed below.

| Common Conflicts During Engineering Development | |

| Conflict | Typical Causes |

| Communication problems |

|

| Varying goals/objective |

|

| Resource constraints |

|

| Execution Issues |

|

| Personality clashes |

|

The list above may not be exhaustive; however, it does cover the most common sources or types of conflict that arise during the engineering process. As indicated, communication issues are often the catalyst and/or effect of conflict. Not surprisingly, effective conflict resolution in engineering strategies depends on good communication.

Strategies for Conflict Resolution in Engineering

Most engineers and other stakeholders likely have a preferred method of dealing with conflicts that may arise during a project. Typical personal conflict resolution techniques include trying to avoid the issue or person(s), giving in to a stronger personality or otherwise trying to be accommodating, assuming a defensive posture or perspective, or striving to be collaborative. Only the last of these–collaboration, which is based on effective communication–is a good individual technique for handling engineering project conflict.

Developing a team strategy requires a more comprehensive approach. Keys that should be considered/adopted are:

|

Conflict Resolution in Engineering Strategy Development Keys |

||||

|

||||

The keys above provide a basis for creating a sound conflict resolution in engineering strategy. However, the degree of success will depend upon the commitment and engagement of the individuals involved. As with all risk management plans, your conflict resolution plan should be a dynamic work in progress that is regularly reviewed and revised based on actual results.

Unlock faster innovation and optimal outcomes with Accelerated Designs. With access to the latest EDA software, diverse data, and the industry’s most comprehensive PCB CAD-content digital library, we provide the tools, technologies, and expertise to reduce development costs, speed time to market, and overcome common design challenges. Contact Accelerated Designs to start optimizing your design process today.