Developing or adopting an effective supply chain resilience strategy is crucial for teams that design and development of electronic products and electronics-based systems, due to the dependence on global networks for sourcing parts and equipment. Disruptions caused by natural disasters, war, trade disputes, or epidemics may cause severe delays and shortages that derail production schedules and can negatively impact profitability. IC manufacturers can play an important role by understanding the most employed supply chain resilience strategies and taking steps to support their success.

The Best Supply Chain Resilience Strategies

Strategies to increase supply chain resilience, such as diversifying suppliers, increasing inventory buffers, and enhancing supply chain visibility, can help electronics development companies maintain continuity, meet demand, and mitigate risks. Here are the most effective supply chain resilience strategies that engineers, ODMs, OEMs, and electronic component distributors employ.

|

BEST SUPPLY CHAIN RESILIENCE STRATEGIES |

|||

|

Strategy |

Description |

Benefits |

Challenges |

|

Supplier Diversification |

✔ Sourcing from multiple suppliers across different regions of the world. |

+ Reduces dependency on a single supplier or region and thus reduces risks of disruption |

− Increased complexity in supply chain management; potential for higher costs |

|

✔ Creating long-term relationships with essential vendors and providers of logistics |

+ Enhances cooperation; improves supply chain visibility; ensures priority in times of shortage |

− Overreliance on partners and possible decrease in flexibility |

|

|

Inventory Buffering |

✔ Keeping a large amount of stock on critical components |

+ Ensures that there are enough materials in stock during supply chain disruption |

− Locks up capital; threat of stock obsolescence in quickly changing markets |

|

Demand Forecasting and Planning |

✔ Using advanced analytics and AI to predict demand and adjust supply accordingly |

+ Better alignment of supply with demand; minimizes incidents of excessive stock or stockout |

− Depends on accurate data and technological support; risk of errors in forecast prediction |

|

Supplier Audits and Risk Assessment |

✔ Monitoring suppliers’ risk factors regularly |

+ Highlights potential vulnerabilities in the supply chain before they result in disruption |

− Time-consuming; could harm supplier relationships |

|

✔ Employing tools for real-time observation of the supply chain processes |

+ Provides the ability to recover from disruptions quickly; improved visibility |

− Large initial investment; needs continuous monitoring |

|

|

✔ Dispersing manufacturing and distribution facilities geographically |

+ Enhances resilience against localized disruptions |

− Large capital expenditures; management complexity |

|

|

Financial Hedging |

✔ Using financial instruments to protect against price volatility for critical components |

+ Mitigates business and financial risk because of changes in the costs of raw materials |

− Increases costs; requires financial expertise |

|

Reshoring and Nearshoring |

✔ Returning manufacturing processes to the home country or nearby regions |

+ Reduces risk exposure from international disruptions; tightens local supply chain |

− Higher wages; …potential shortage of skills and talent |

|

Digital Twin and Simulation |

✔ Understanding how the supply chain works by creating a virtual model and testing it using a set of various assumptions |

+ Enables proactive identification of supply chain issues and testing of mitigation strategies |

− High execution costs; requires accurate and comprehensive data |

How IC Manufacturers Support Resilience Strategies

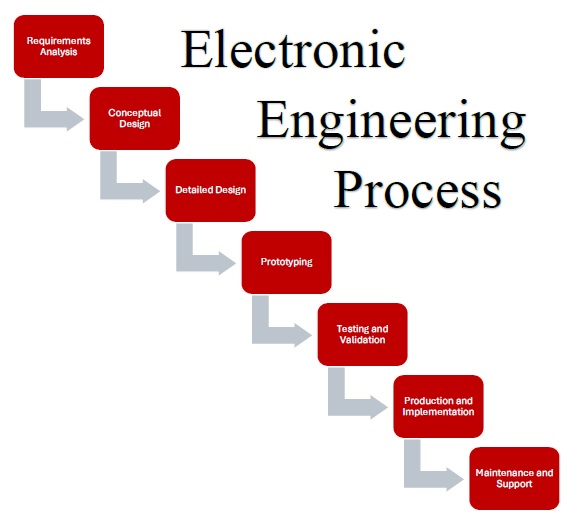

Ultimately, the purpose of supply chain resilience strategies are to help engineers and developers execute the development and production of electronics devices and systems as efficiently as possible. Achieving this goal is not possible unless engineers and PCB manufacturers can get the parts they need when they need them. This is where IC manufacturers can have significant impact.

IC Manufacturer Guidelines for Impacting Supply Chain Resilience Strategies

- Take steps to ensure your manufacturing process(es) is not susceptible to supply chain disruptions

- Research and understand your clients component sourcing needs

- Optimize your distribution channel usage

- Provide pertinent and insightful content about your products and services

- Leverage marketing KPIs and statistics and revise your strategy as needed

As this list indicates, the best way to help your clients achieve supply chain resilience is by meeting their needs for accurate date and component availability, irrespective of their chosen resource for acquiring and/or procuring them. The best option for addressing all of these important keys is by partnering with the industry’s most relied on provider of electronic component data, CAD models, and secure distribution source integrations, Ultra LIbrarian.

Discover how Ultra Librarian helps manufacturers. With services and resources tailored to streamline CAD creation and amplify part downloads, Ultra Librarian empowers manufacturers to boost productivity and drive part downloads. By leveraging these tools, manufacturers can achieve greater success in today’s competitive market landscape.